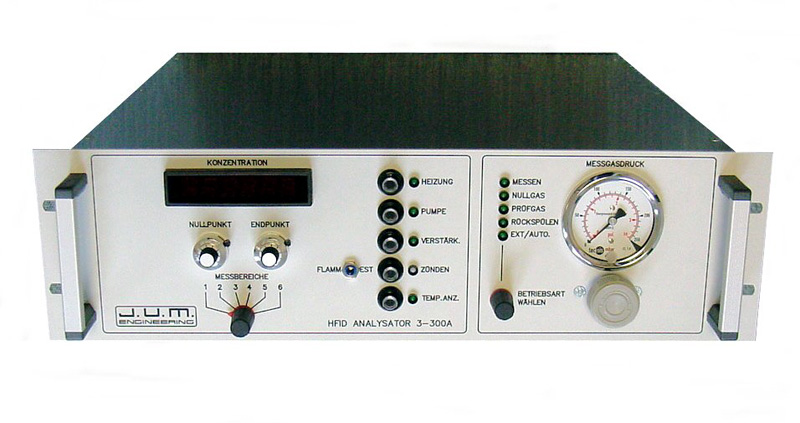

The Model 3-300A was designed in the early 80’s as a space saving alternative to our many thousand fold VE7. The 3-300A was a also “first” in the industry due to its sample filter back purge feature. It is also a very much liked 19″ rack mount heated FID throughout the stack testing community and well known for its ruggedness, forgiveness and long standing accuracy and sensitivity. The 3-300A is fully identical to the VE7 and 3-200 and has been officially approved for that.

TÜV confirmed to fully comply with QAL 1 (EN 14 181 and EN ISO 14956) and EN12619 regulations. They also fully complies with USEPA Method 25A and Method 503.

The 3-300/OVE

is a 100% identical version at 20% lower cost due to the use of a disposable sample filter in the heated oven. With this exception the 3-300/OVE is a 100% identical analyzer.

Features:

- Maintenance free sample filter back purge system allows filter to be cleaned without dismantling (automatic optional)

- Built in burner air generator, no external air cylinder needed

- All components in contact with sample fully heated and controlled at 190 degree C

- Built-in sample pressure and sample pumps

- Automatic flame out alarm and contact

- Fast response within 1 second

- Low fuel consumption

- Very selective

- Microprocessor controlled PID temperature controller

- Remote control for sample, calibrate and back purge is standard

- Remote or automatic range change optional

Applications:

- Stack gas hydrocarbon emissions monitoring

- Fence line monitoring

- Raw exhaust vehicle emissions analysis

- Catalytic converter testing

- Measuring engine combustion efficiency

- Hydrocarbon contamination monitoring in air and other gases

- Carbon adsorption regeneration control

- Detection of trace hydrocarbons in purity gases used in the semi conductor industry

- LEL monitor of solvent laden air